- FREE SHIPPING On all orders

- SUPPORT 24/7 We support online 24 hours a Day

Every product has a specific size and features. That’s why professional suppliers have come up with an endless variety of customized packaging solutions that fit best a wide variety of product types and sizes. However, choosing the correct-sized custom box dimensions is essential to ensure the product’s integrity during display or shipping. This helps brands provide high-quality products every time and build a firm trust among buyers that can ultimately boost their product’s sales and profitability.

So, what are you waiting for? Let’s explore the typical box dimensions and learn how to measure a box. Scroll down this quick and detailed guide and find out all the measuring dimensions of a custom box that forms a precise, sturdy, and accurate custom-printed box.

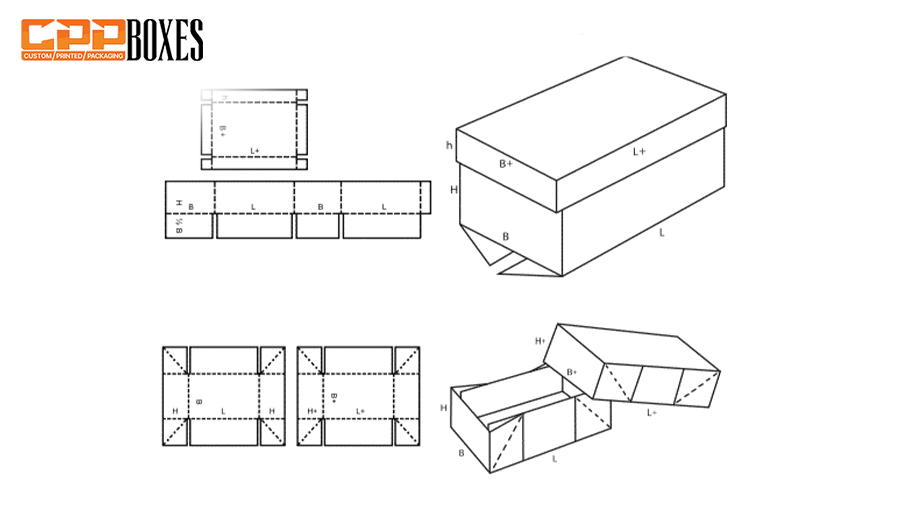

Typical box dimensions greatly vary depending on the box type, feature, and usage. In the packaging industry, mm and inches are preferably used to measure box dimensions, such as length, width, height, or depth. Let’s give a quick read to all the standard box dimensions that must be accurately measured to design a perfect-fitting custom box:

Typical box dimensions greatly vary depending on the box type, feature, and usage. In the packaging industry, mm and inches are preferably used to measure box dimensions, such as length, width, height, or depth. Let’s give a quick read to all the standard box dimensions that must be accurately measured to design a perfect-fitting custom box:

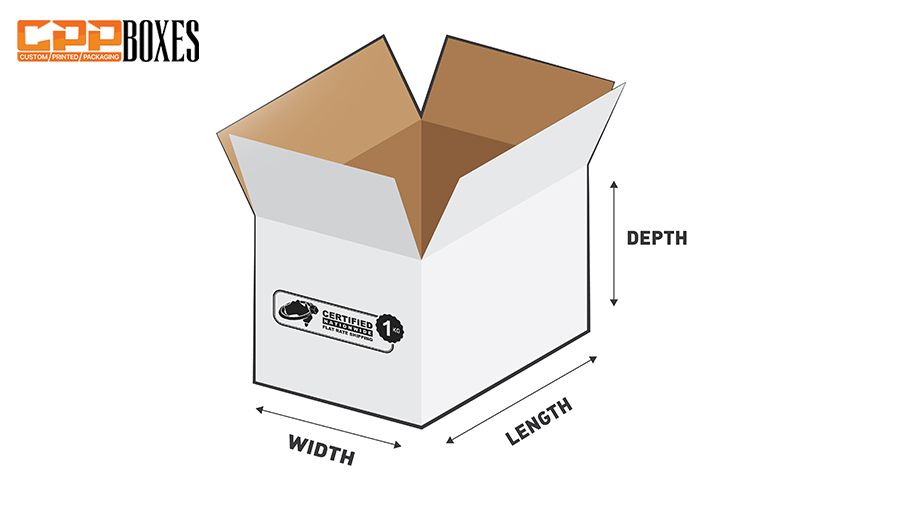

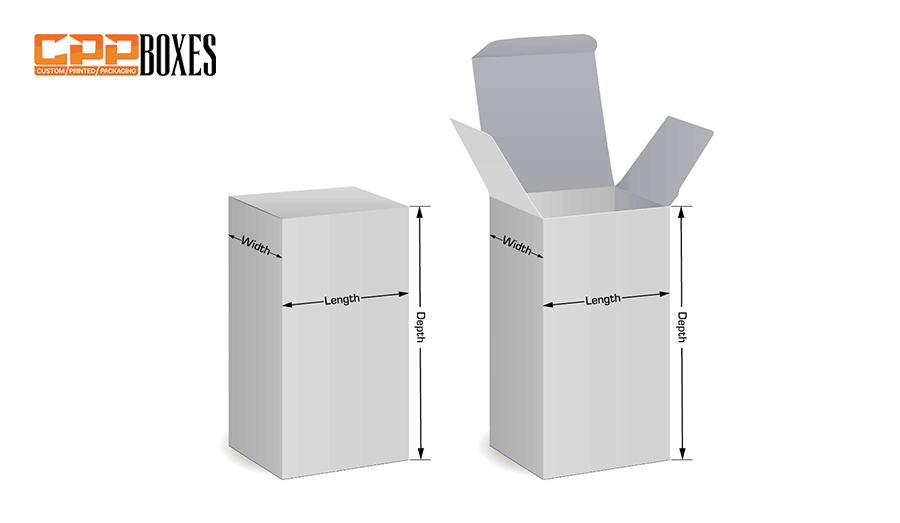

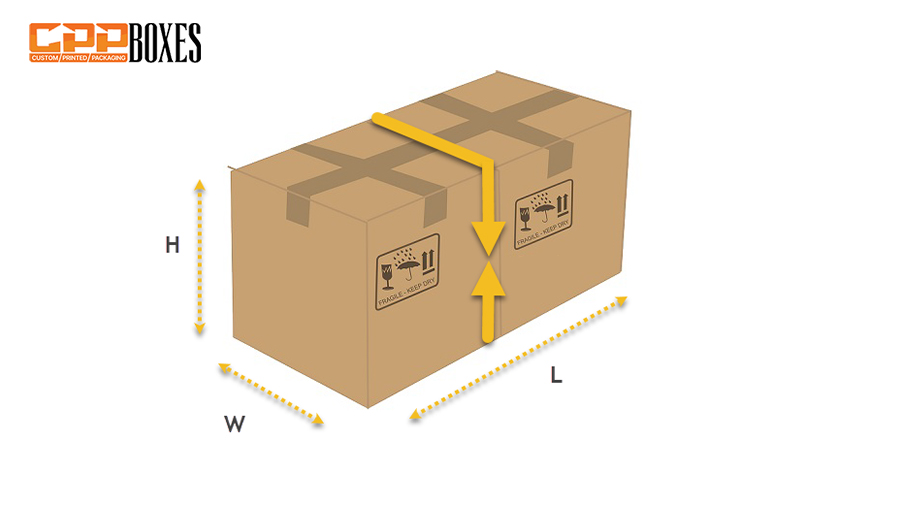

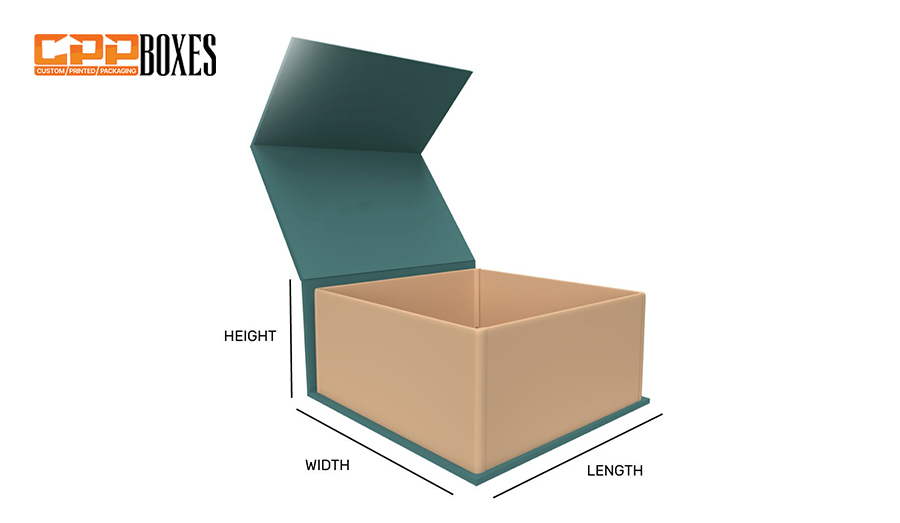

It’s the longest side of the custom packaging box that defines the base orientation of the box. Represented as “L”, a box’s length is usually measured from one longer side to another.

Perpendicular to the box’s length, the width is defined as the shorter side of the base. After length, width is the major dimension that defines the perfect sizing and shape of custom-printed packaging boxes. It ensures a lateral space around the packaged product.

It’s the vertical dimension from the base to the top of the packaging box. Properly heighted box, designed according to the packaged item’s dimensions, ensures proper clearance, especially for the lid-style packaging boxes.

Defined as the amount of 3D space enclosed within a packaging solution, a box’s volume is measured by multiplying length, width, and height, such as L × W × H. It’s typically measured in cubic units, including cubic inches, cubic centimeters, or liters.

The following are some of the recommended typical dimensions for various-sized custom packaging boxes. Fluctuations are expected as per the product’s needs and demands:

| Box Type | Dimensions(inches) |

| Small | 16" x 12" x 12" |

| Medium | 18" x 18" x 16" |

| Large | 18" x 18" x 24" |

| Extra Large | 24" x 18" x 24" |

| Dish Pack | 18" x 18" x 28" |

Here’s a brief overview of all the most common and famous custom packaging solutions with their recommended dimensions:

| Box Type | Recommended Dimensions (L × W × H) |

| Mailer Box (Roll-End) | 9 × 6 × 3 in |

| Shipping Box (RSC) | 12 × 9 × 6 in |

| Rigid Mailer Envelope | 12.5 × 9.5 × 0.5 in |

| Tuck Top Box (TTAB) | 6 × 4 × 2 in |

| Sleeve Box | 7 × 5 × 2 in |

| Pillow Box | 7 × 5 × 2 in |

| Drawer Box (Matchbox Style) | 5 × 3 × 1.5 in |

| Gable Box | 8 × 5 × 5 + 4 in (handle height) |

| Display Box (POP) | 10 × 6 × 3 in |

| Auto-Lock Bottom Box | 8 × 6 × 4 in |

| Wine Box (2-Bottle) | 13.5 × 7 × 4 in |

| Magnetic Closure Box | 10 × 8 × 4 in |

| Eco Foldable Box | 9 × 6 × 2 in |

“How to measure the dimensions of a box?” It’s the most common question, often asked by brands or individuals while purchasing custom-printed packaging boxes. For convenience, we have broken down the detailed measuring process in simple steps. Before reading out the step-wise measuring process, check out the following measuring tools that you need for the accurate measurement of custom boxes:

Measuring tape: A flexible and precise tool that measures the box’s length, width, and height in inches/cm.

Ruler/Scale: It is preferred to measure smaller boxes or detailed box parts in mm/in.

Digital caliper: Ideally used to measure very precise internal/external distances and material thicknesses.

Box dimension tool: It’s a special L-shaped box ruler or folding tool to easily measure the packaging.

Triangle or set square: Used for checking box structure, this measuring tool ensures right angles or box squareness.

Laser distance measurer: It’s a fast and accurate measuring tool, recommended for large shipping crates or bulk purchasing.

Notebook/ digital app: They are required to keep records of the measurements.

Let’s find out the exact box dimensions by following the simple steps given below:

First, lay out the products on a flat surface and measure their sizes. Then, open the box and visualize its interior to make an accurate assessment of whether the box is suitable for your product’s packaging or not.

Consider the box’s internal dimensions, despite the box’s thickness, to ensure the accurate measurement of the box’s dimensions, such as length, width, height, and volume. Use a measuring tape or ruler to find out the box’s internal measurements and jot down the measurements in a notebook or a digital app. Here’s how you’ll measure the box’s length, width, height, and volume:

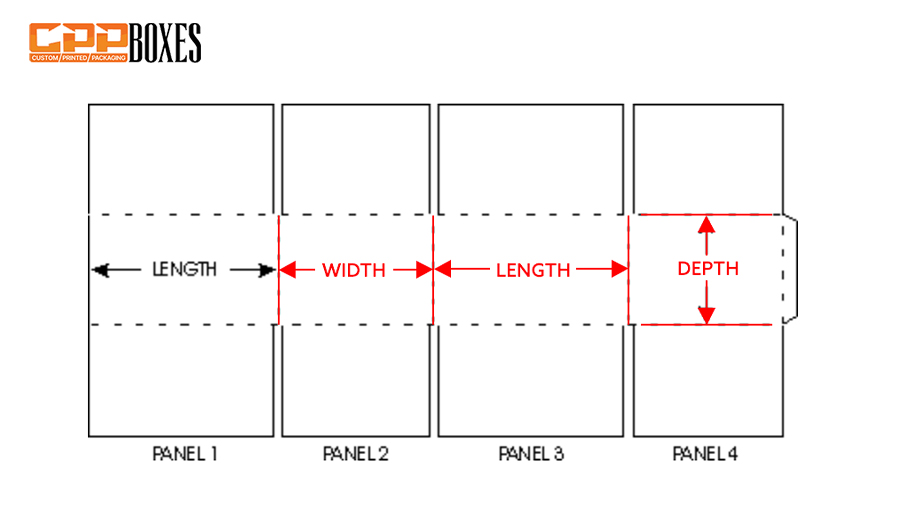

Take the inside edge of the box, from left to right, along the bottom of the custom packaging box. Choose the side with a flap. Use a measuring tape or a ruler, and place it flat against the inner wall of the box. Here is a key to remember that if you have a book-style or a clamshell packaging solution, then the opening flap always runs along the box’s length. After measuring, if you get a 10-inch internal base from left to right, then the exact length of the custom box will be 10 inches.

For the box’s accurate width measurement, place the box in an upright position. Consider the inside edge from the front to the back direction of the box’s base. Pick up the side that’s 90° to the length of the box’s base. For example, if the inside from front to back is 6 inches, it means the overall box’s width is 6 inches in measurement.

To measure a box’s height or depth, consider the inside wall and measure from the bottom to the top edge. For accurate measurements, place the box on a flat surface and measure from the inner base straight up to the open top. In case of tuck-top or custom lid boxes, measure from the box’s bottom to the top edge of the side panel. For instance, if the vertical inner side wall is 4 inches tall, the box’s overall height will be considered 4 inches.

Once the box’s length, width, and height are calculated, obtain its volume by multiplying all these dimensions (L × W × H) and get the accurate box capacity to hold a specific weight of items. Volume estimation is compulsory to have a correct shipping cost analysis, filler material calculation, and space optimization. Typically, the box’s volume is measured in cubic inches, centimeters, and liters.

Make sure to follow the order of measuring custom box dimensions in such a way that length is measured first, then width, and then height. After calculating these primary dimensions, calculate the total volume.

After calculating the box’s basic dimensions, consider measuring the following dimensions for more accurate results:

Measure the exact sizes of tuck or dust flaps, often present in different box types, to ensure a safe box closure. Usually, 1 or 2 such flaps are present in a box, depending on the box size. Custom tuck top and mailer boxes are some of the most common examples where flap dimensions calculation is compulsory.

Many custom boxes are available with hinged lids, magnetic closures, or fold-over flaps. For such boxes, you must include extra space or panel length for accurate measurements. The best way is to first measure the lid overlap or fold-over lines separately on a dieline and then add them to the other calculated box dimensions.

Considering material thickness is crucial to find out the overall shipping volume of a packaging box. Different materials have variable thicknesses. Therefore, calculate the material thickness and opt for the packaging box with enough strength to perfectly hold and ship your desired number of products.

Though the box’s internal dimensions mean a lot in calculating the exact dimensions, measuring external box dimensions is also essential to ensure a best-fit packaging for your valuable products. External box dimensions are generally measured by adding the material thickness to each dimension twice (once per side).

Round up the box slightly and check out for product wiggle room, space for packaging inserts or padding, and ease of product removal. This ensures you a comfortable packaging for the storage, display, and shipping of your valuable products.

After making the required measurement adjustments, write down the box’s dimensions in a physical notebook or a digital application. Jot down these measurements in standard units, such as inches, cm, or mm.

At last, add extra spaces depending on the material thickness, product protection, shipping movement, and other such features.

Here are some simple steps to determine the custom box dimensions digitally:

The following are some of the most vital tips that you must not overlook while measuring the custom box dimensions. They ensure an accurate sizing of bespoke boxes. Let’s have a look at them:

Do you want the accurately-sized custom-printed packaging boxes for the storage, display, and shipping of your valuable products? Turn to CPP Boxes, your trusted partner for an endless variety of custom packaging boxes, available in all sizes. Visit our official website to get an instant quote or directly contact us at 888-395-0493 or quotes@cppboxes.com to share your custom box size requirements and stand out with precise product packaging on the store’s shelves.

This design offers good protection and a premium unboxing experience.

GET YOUR QUOTE

.webp)

Blake Harper is an experienced and dedicated packaging engineer with a deep passion for creating innovative, sustainable, and cost-effective packaging solutions. He holds a degree in Packaging Engineering, where he gained a strong foundation in materials science, product design, and manufacturing processes. With years of hands-on experience, Blake has honed his skills in optimizing packaging designs for a wide range of industries, including consumer goods, electronics, and food packaging.

Currently, Blake has been with CPP Boxes, a leading packaging solutions provider, for several years, where he has played a key role in designing packaging that balances functionality, cost efficiency, and sustainability. His work at CPP Boxes has involved designing protective packaging, improving supply chain logistics, and developing eco-friendly solutions that reduce waste and environmental impact.

Blake's expertise lies in selecting the right materials, creating structural designs that maximize protection and minimize costs, and ensuring that packaging meets both consumer expectations and industry standards. His approach integrates creativity with technical know-how, always striving for solutions that are both practical and innovative.

Passionate about environmental sustainability, Blake is always exploring new ways to incorporate eco-friendly practices into his work. He is committed to advancing packaging technologies and methodologies that reduce waste, improve recyclability, and contribute to a more sustainable future. Throughout his career, Blake has become known for his strong problem-solving skills, attention to detail, and his ability to collaborate effectively with cross-functional teams to meet project goals.

Whether it’s food, healthcare, technology, cosmetic...

May 14, 2025